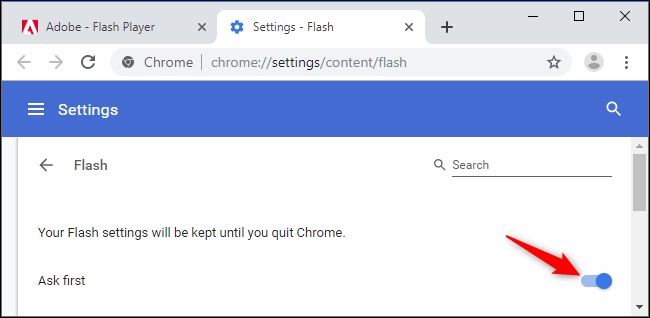

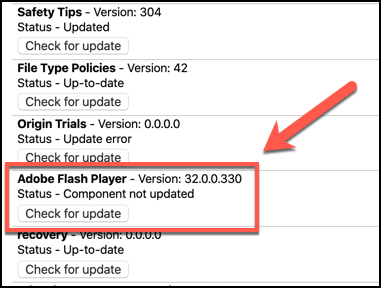

Shockwave flash has crashed in Google Chrome is quite a common incidence for Chrome users when they are streaming videos on the browser. Google Chrome uses an in-built shockwave flash unlike other browsers that use the host system flash to perform the video streaming function. If after all that you still want to enable Flash in Google Chrome, here is how you do it. Open Chrome and select the three vertical dots and then Settings. Select Advanced at the bottom of the.

- Flash Chrome 71

- Flash Chrome Android

- Flash Chrome Plating Near Me

- Flash Chrome 2020

- Flash Chrome Download

Hard chrome plating deposits are widely used to provide a hard, abrasion resistant surface, and also for building up worn or undersize parts.

Iterations of hard chrome include:

- Flash Hard Chrome

- Thin Dense Hard Chrome

- Pure / Nodular Hard Chrome with out Hard chrome build up.

Hard chrome plating deposition on rollers, cylinders and shafts. These parts are used in many kinds of machines; paper making and printing machines, embossed cylinders for wallpaper and other materials, rollers used in the manufacture of plastic sheet and film, shafts used in hydraulic equipment see Industries served and plating solutions

Chromplate provides two types of Hard Chrome plating service:

| Standard Hard Chrome A high quality hard coating (hardness approx. 950-1050 Vickers or 68 Rockwell C), which can be applied in a range of deposit thickness to suit your requirements. See hard chrome build up. | Flash Hard Chrome - |

Micro-Cracked Hard Chrome (Bright)

This type of hard chrome offers a number advantages over the standard Hard Chrome...

Flash Chrome 71

- Harder and more wear resistant (hardness appox. 1050-1150 Vickers or 70 Rockwell C).

- Offers better corrosion protection than standard hard chrome

- Brighter finish than hard chrome

These extra qualities make this mirco cracked hard chrome ideally suited for use with hydraulic rams which may be operating in dirty environments, if dirt is liable to lodge in seals, less harm may be done to the ram. For wet or salt-water environments, an under coat of nickel plating provides a corrosion resistant layer, that extends the working life of the ram considerably.

This chrome is also well suited to any application that standard chrome is also used.

Before & After Treatment of Hard Chrome

Other operations may be required, prior to, and after chrome plating...

- Pre-machining to supplied dimensions or surface finish tolerances.

- Finish machining and polishing to supplied dimensions or surface finish tolerances.

- Nickel-plating for a corrosion protective layer.

- Shot/grit blast before or after plating to produce a textured/matt finish or for de-embrittling the material prior to chrome plating.

- Heat treating before/after plating for de-embrittling or degassing to relieve stresses in the material or remove trapped gasses which may cause problems when the roll is used in plastic and film manufacturing processes.

Flash Hard Chrome - | Special Note on Hard Chrome It is a common misconception that chrome plating provides corrosion protection. This is not the case, only slight protection is given. Hard Chrome is porous at the microscopic level, which can let moisture and chemicals through to attack the base material. If the item is to be used in a damp environment, or where water based inks are used on printing machines, a layer of Nickel plating is required, prior to hard chrome plating. |

Flash Chrome Android

We offer a flash chrome plating service based on Chromic Acid - Chromium Trioxide Flake from Elementis. Our solution is made up of 250g/l CrO3 and Sulphuric Acid at a 100:1 ratio.

Process: Flash hard chrome plating is an electrolytic process utilising a chromic acid-based electrolyte. The component requiring plating becomes the cathode and, with the passage of a DC current via anodes, chromium metal builds on the component surface.

Background: Flash hard chrome plating, also referred to as functional chrome plating, is applied as a thinner layer. It is ideal for close tolerance applications where an excessive build up of chrome is undesirable and where the requirement is to provide a durable hard wear-resisting surface.

Applications: Flash Hard Chrome plating has many typical applications, some of which are detailed below:

- Wire wound rods for paper coating

- Seal areas on pump or drive shafts

- Conveyer guide rails and rollers

- Plastic extruder screws

- Hydraulic rams and cylinders

- Print rollers

Tanks: We offer tank sizes up to 3.6m long.

Thickness: Coating thickness is dependent on the application and the customers’ requirements, which can normally range from 10 to 25 microns. This smaller deposit of hard chrome usually eliminates the need for a grinding operation to finish.

Hardness: Hardness is in the region of 950 - 1150HV.

Materials: Most materials can be Flash Chrome plated, including:

Flash Chrome Plating Near Me

- Steel

- Stainless Steel

- Cast Iron

- Copper

- Brass

- Bronze Alloys

- Nickel Alloys

Plating Vats: We have the capacity to chrome up to 3.6metres in length and if you think you may have a possible application for a component not listed, please contact us to discuss this further.

Stopping Off: Selective Hard Chrome plating can be achieved through masking with clamca wax or stopping-off lacquer.

Etching: Etching is carried in accordance with the guidance relevant to the base material being plated. All components are etched before Hard Chrome plating to provide a good key for the hard chrome deposit to be applied.

Flash Chrome 2020

Jigging: Careful jigging is required for hard chrome plating, taking into consideration current carrying capacity and weight of component. Special attention is necessary for the plating of internal surfaces. One of the characteristics of hard chrome is its poor throwing power, therefore auxiliary anodes maybe required at strategic locations.